So you've got your hands on a new boat and you're keen to get out on to the water to show the family a different side to New Zealand – and maybe pick up a few fish on the way.

You may well have all good intentions when it comes to looking after your boat: flushing out the motor, keeping the hull weed-free, hosing her down after every use – that sort of thing. But there’s still an insidious source of corrosion you need to understand and fight.

Galvanic corrosion takes you right back to science class! In short, it happens when you get two different types of metal suspended in a liquid which can conduct electricity – and seawater is just one of those liquids.

There’s heaps of technical jargon involving electrons and ions around how galvanic corrosion works, but the long and short of it is that some metals are “stronger” than others – these are called cathodes – and cause “weaker” metals – known as anodes – to corrode more rapidly when they’re in the water together.

For example: if you have “strong” bronze, copper or brass fittings on a “weak” aluminum hull (and most boats are going to have various metal fittings and materials), that hull is going to suffer from corrosion unless you take steps to prevent it.

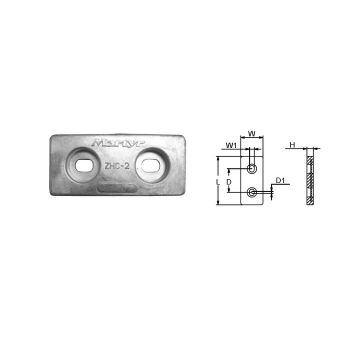

What you need is a metal which is “weaker” than aluminium which can play the role of the anode instead of the hull… in other words a sacrificial anode. Fortunately, zinc is exactly this type of metal, which means you can connect a zinc sacrificial anode to the aluminum (either by direct contact or by wire) and let that corrode instead of the hull.

So here’s our 8-point guide to using sacrificial anodes:

- Treat every metal fitting as a separate corrosion zone – ie you’ll potentially need sacrificial anodes for your motor, prop, hull, etc.

- Try not to mix metals – this is especially important when you’re fitting new bolts.

- When first fitting anodes, gauge how many you’ll need by fitting a few small ones rather than one large one. Check them each month to ensure they’re corroding – if they’re not, check they’ve got a good contact with the aluminum. Ideally, you’ll want to be replacing them each spring.

- Don’t paint over your anodes and make sure they’re securely fastened to the metal they’re designed to protect. And remember, they’re going to erode pretty rapidly so they’re going to need to be fastened in a way they don’t come free even once they’ve corroded.

- Use paints and primers specially designed for aluminum and repair any dings which expose bare metal as quickly as possible.

- You can prevent a certain amount of galvanic corrosion by isolating fittings from each other – this includes making sure they aren’t sitting in seawater too long.

- Electric currents accelerate the corrosion hugely so don’t use a car battery charger aboard a boat and always use an isolation transformer if you connect to AC shore power.

- Metal debris in your bilge – or even sitting in the bottom of your boat – can lead to galvanic corrosion so clean up bottle tops and fishing gear such as hooks and sinkers.

For more information on Burnsco's antifouling range, phone us on 0800 102041, email us, or Livechat with one of our staff via the website.