Marine toilets with dual function pumps draw their own flush-water from a seacock or a water tank and pump the waste to either another seacock or a holding tank. Their capacity to pump waste generally far exceeds their flush water pumping capacity, which means that the bowl is completely emptied.

Hoses & Connections

- It's important to use only high-grade sanitary hose. All pliable hoses are permeable to some degree, and only a quality sanitary hose will keep odour in control (odorous gases can completely saturate lower quality hose, and stink for months after all waste has been removed). All connections should be double hose-clipped (with the clips counter-opposed). Careful use of a heat gun to soften hose ends is recommended. Use quality, all stainless steel clips/clamps, and subject joins to a 'pull test’.

- Big hoses incur big stresses on connections, and the consequence of a failed connection can be more than unpleasant - FAILED UNDERWATER CONNECTIONS SINK BOATS! Hard plastic (domestic) piping should be avoided - it was not designed to handle the stresses induced by a moving boat in a seaway.

- Avoid constrictions caused by small-bore fittings and sharp bends. Some seacock valves are quite narrow - use full-flow types where possible.

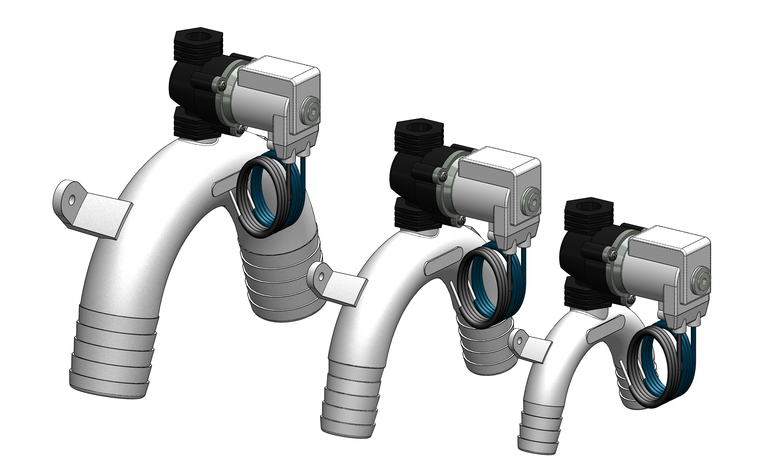

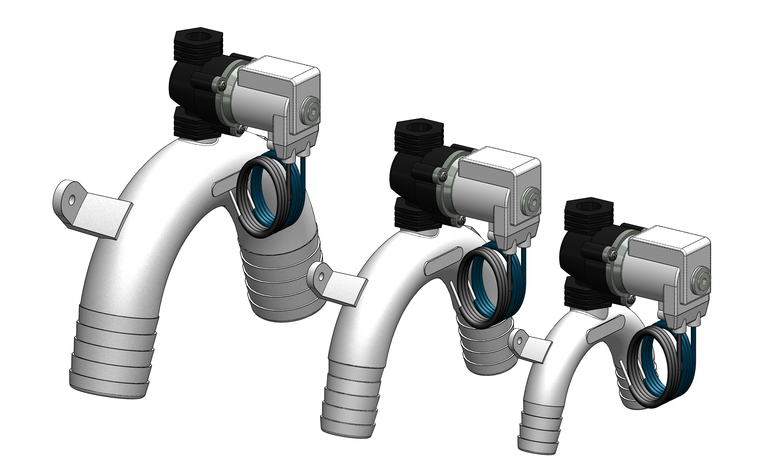

- Do not bend hoses too tightly. The minimum bend radius of our sanitary hose is approx 125mm for 25mm hose, and 190mm for 38mm hose. Tighter bends not only invite the failure of the hose (often in the most difficult-to-see or access location), they also place undue stress on connections. Use 90° bends where necessary. Stretching (on the outside of a tight hose bend) also increases the permeability of the hose, with unwelcome results.

- Protect hoses from chafing. Support long runs of hose at regular intervals with multistraps. Also, protect the hose where it passes through bulkheads.

A Note on Fittings

We recommend using Trudesign fittings wherever possible, for the following reasons:

- They don’t require earth bonding after installation

- No corrosion problems associated with electrolysis

- They are as strong as brass fittings

Electrical Connection

Toilet pumps use surprisingly little power due to the short running times involved. When in use, however, demand can be over 200W (up to 20 amps in a 12v system). Supply cable size should at least match those attached to the motor and switch. Cable runs in excess of 3-4 mts should be upped in size to avoid voltage drop and over-heating. Install the fused switch box in plain sight and within easy reach of the toilet user.

When Connected to a Holding Tank

If the tank is situated below the toilet, it is necessary to create a water trap to prevent smells from the tank coming back through the toilet. This is accomplished by having a riser loop in the outlet hose (approximately 400mm minimum height for manual toilets, and 300mm minimum height for electric toilets) which will retain sufficient water in the base of the toilet to form a trap. Alternatively, you will need to install or create a trap elsewhere in the line

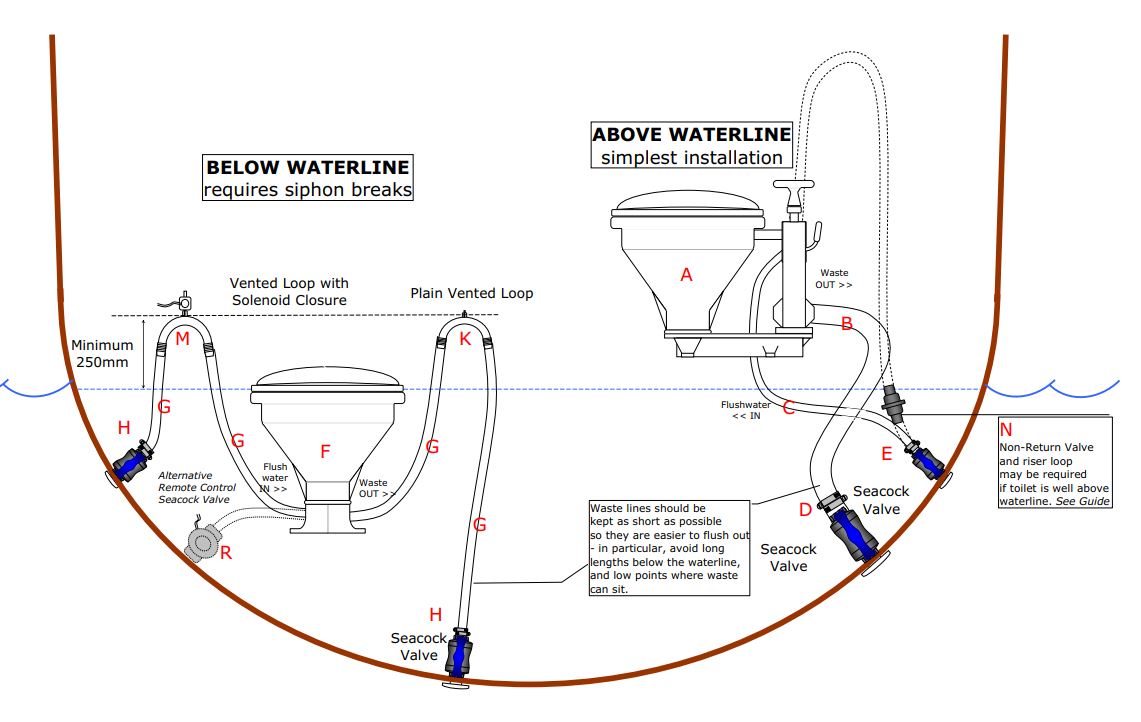

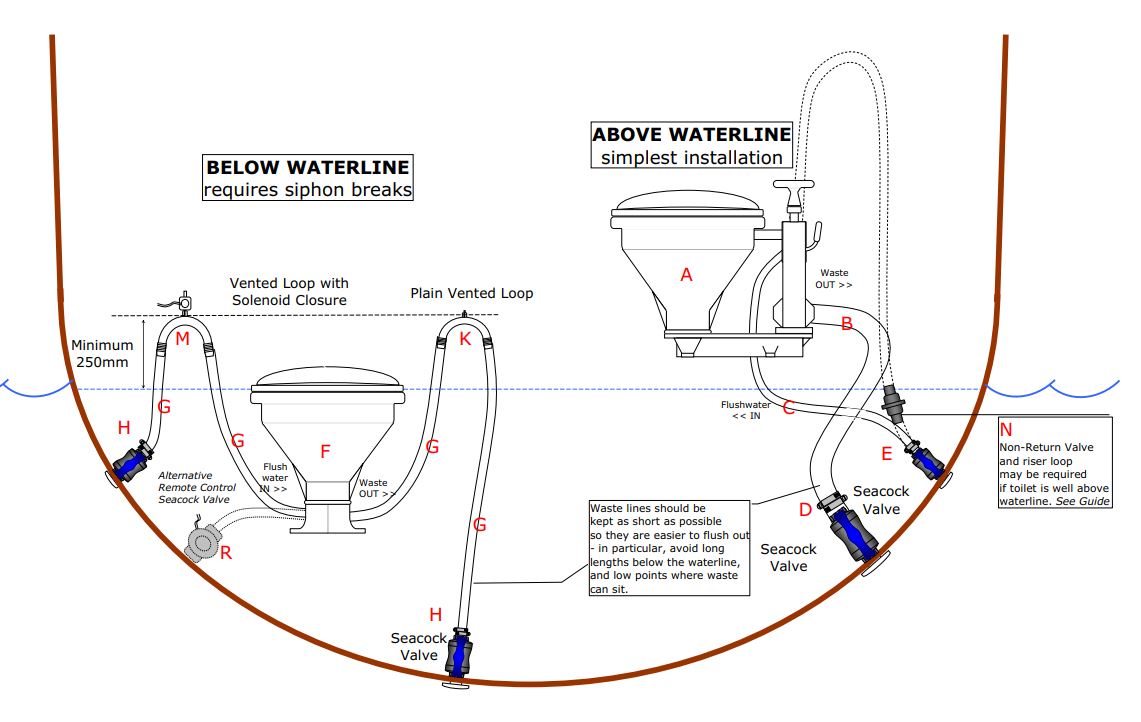

Toilet at or Below Outside Water Level

It is normal, safe boating practice to close all seacocks when no-one is aboard. However, when seacocks are open, toilet valves/seals and impellers (which are subject to interference and aging/hardening) cannot be relied upon to prevent siphoning of seawater into the toilet, and then into the boat. Manual toilets have a 'dry-bowl' lever to lock off the flush water supply, and everyone on board must be instructed to close this after use. Electric toilets have only a rubber impeller to prevent back-flow. Even when all parts are in as-new condition, a serious risk exists.

IF THE TOILET HAS DIRECT OR INDIRECT CONNECTION TO THE SEA, WE STRONGLY RECOMMEND THAT YOU INSTALL VENTED LOOPS (siphon breaks), particularly in the waste outlet. Even if seacock valves are easily reached (and routinely used), FAILURE TO INSTALL SIPHON-BREAKS MAY SINK YOUR BOAT!

Note about flush water siphon breaks: under suction, plain vented loops will allow air into the system, de-priming and preventing the pump from drawing any flush water. To prevent this you might consider using a line-valve instead, in an accessible location. But a better option, especially with electric toilets, is a solenoid-controlled vented loop, which can be wired into the toilet switch providing automatic operation (see below).

Toilet Above Outside Water Level

Flush water can be drawn several meters, and up to a meter in height. Note, however, that water can fall away, de-priming the pump between uses. A non-return valve close to the tank can fix this problem, but it requires a good head of water on top (via a riser loop) to keep it functioning. If a riser loop is impractical, a manually operated line-valve or an electrically controlled solenoid valve (wired to the toilet switch) may be required in the flush water supply line.

Do you have any questions?

Please, contact our friendly team on 0800 102041 or email: website@burnsco.co.nz